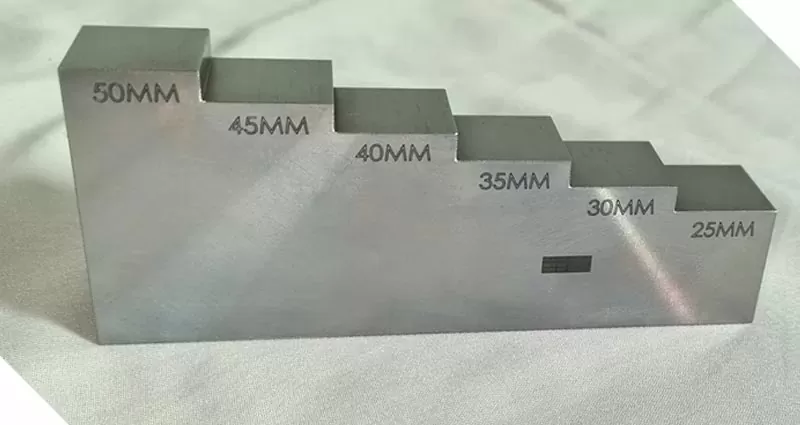

Understanding Calibration Blocks: An Essential Tool in Precision Engineering

Calibration blocks are a mainstay of non-destructive testing (NDT). They’re used to detect flaws within a component and can be utilised with various testing methods, including ultrasonic testing (UT), eddy current testing (ET), phased array (PA), advanced ultrasonic testing (A-UT) and time of flight diffraction...