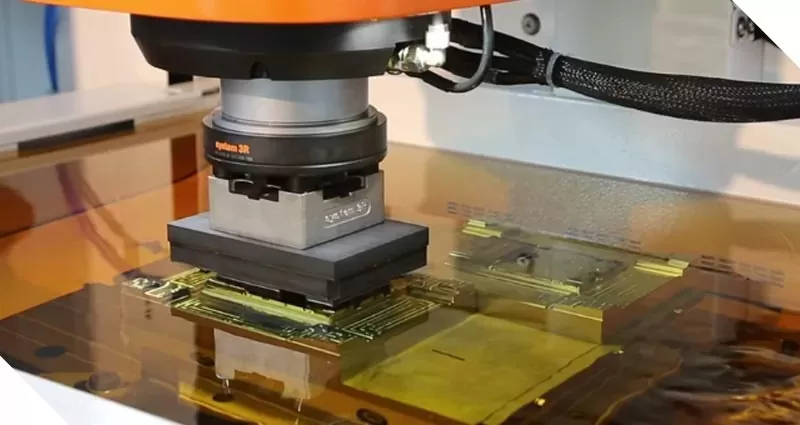

The SixDe EDM Plunger / Sinker Difference

Many companies offer EDM plunger / sinker services, so what makes SixDe different? In addition to being a leading subject matter expert serving Perth, Western Australia and the wider nation, customers benefit from the following:

- A design team that works with you from the outset to understand your machining needs

- Full design and manufacturing support for CAD/CAM part creation throughout the process

- The expertise to determine the ultimate machining solution for the parts required

- Servicing all your precision machining needs, from prototypes through to large production quantities

- Fast and economical production abilities

- Can work with virtually every material, including stainless steel, titanium, copper, silver, iron, tungsten and many more.

- Access to the very latest precision machining technologies

- Outstanding customer service – logistics, design and despatch that’s second to none

SixDe engineers have specialised in spark erosion-sinker EDM capabilities for decades. Offering the ultimate solution for parts that require the accuracy that defies traditional manufacturing techniques, the technology is often utilised for EDM parts within industries, such as aerospace, medical, defence and OEM.

The accuracy delivered can be as fine as 0.02mm and is achieved in timescales that are far superior to conventional machine techniques. This makes SixDe EDM plunger / sinker capabilities one of the fastest, best value choices for when pinpoint precision is required.

In addition, the SixDe processes all conform to stringent Australian and international requirements. This guarantees peace of mind throughout production, ensuring traceability, quality and delivery.

Partner with SixDe Today

The first stage of your SixDe journey is the initial enquiry. This no-obligation step allows our customer service team to connect you with our specialist design engineers who’ll discuss your requirements. From here, the journey moves on to accurate part design and the best precision machining method for the project.

Our service model is designed around a speedy, accurate delivery that’s economically viable. This is mirrored across our whole process – from prototyping to full production quantities. If required, we can provide examples of previous projects. Initial consultations can take place at our Perth offices, your facility or via video chat.

The accuracy of your EDM plunger/sinker requirements should be matched by the varied manufacturing capabilities of your chosen provider. At SixDe, this industry expertise extends to our complete manufacturing portfolio, including precision machining, CNC machining, 3D printing, calibration blocks and more.

Get in contact today to arrange your initial, no-obligation discussion.